The Evolution of 3D Filaments: What’s New and Exciting?

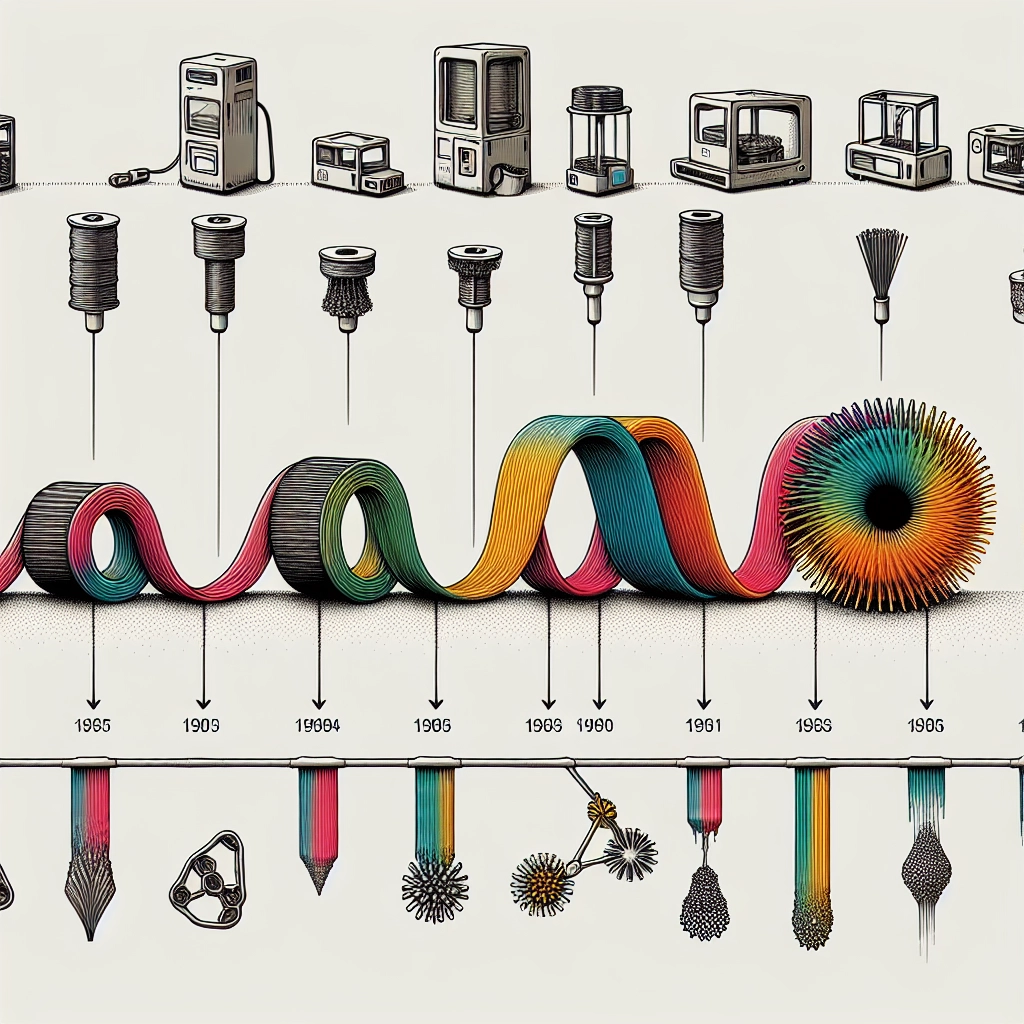

If you’re diving into the world of 3D printing or you’re already a seasoned maker, you may have noticed a fascinating shift in 3D filaments over the past few years. As technology rapidly evolves, so too does the array of materials available for printing. From the classic PLA to more exotic blends, let’s take a closer look at the advancements in 3D filaments that are stirring excitement among enthusiasts and professionals alike.

A Quick Recap of 3D Printing Basics

Before we get into the exciting advancements, let’s quickly review what filaments are. In 3D printing, especially with FDM (Fused Deposition Modeling) printers, filaments are the plastic materials that are melted and extruded to create objects layer by layer. The most common types are PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), and PETG (Polyethylene Terephthalate Glycol). Each material has its unique properties and applications, but now we’re seeing innovation that expands capabilities beyond these traditional choices.

Biodegradable and Eco-Friendly Options

One trending development is the rise of eco-friendly filaments. As environmental consciousness grows, manufacturers are responding with biodegradable materials. New formulations like PLA blends that include recycled or organic components are not only reducing plastic waste but also supporting a sustainable future for 3D printing.

For example, some companies are now creating filaments derived from plants, such as hemp and wood, which give printed objects a unique aesthetic and texture. Imagine the possibilities—3D printed objects that look and feel like they were made from natural materials but still offer the design freedom that 3D printing provides!

Composite Filaments: Strength Meets Creativity

When durability meets versatility, you get composite filaments. These are made by mixing standard filament materials with additives like carbon fiber, glass fiber, or metal powders. The result is a filament that boasts remarkable strength, heat resistance, and dimensional stability.

Carbon fiber-infused filaments, for instance, are gaining traction because they create lightweight yet rigid prints ideal for industries such as aerospace and automotive. Additionally, these composites open up a broader realm of creative possibilities. Imagine designing custom parts that not only perform well but also look striking—with a beautiful matte finish and strength to boot!

Functional and Specialty Filaments

As 3D printing moves into more specialized fields, so do the materials we use. Specialty filaments designed for specific applications are on the rise, allowing makers and engineers to tackle complex projects.

Take, for instance, flexible filaments like TPU (Thermoplastic Polyurethane). They enable creators to make rubber-like prints that bend and stretch, perfect for prototypes or functional parts like gaskets and seals. Then there are high-temperature filaments like PEEK (Polyether Ether Ketone) that are used in demanding industrial applications requiring resistance to heat and chemicals.

We’re also seeing innovative materials that change properties with various environmental conditions, sparking interest in smart 3D printing. Imagine printing an object that can change color based on temperature or light!

Color and Texture Innovations

In addition to functional improvements, the aesthetic side of 3D printing is also evolving. Filament manufacturers are increasingly offering vibrant colors, effects, and finishes that can add character to printed models.

Metallic, translucent, and even glow-in-the-dark filaments are becoming staples in the 3D printing world, allowing hobbyists to craft eye-catching designs. Plus, advancements in multi-material printing are enabling users to create objects with varying colors and textures in a single print. It’s creativity unleashed—a sight to behold!

Conclusion: The Future of 3D Filaments

The world of 3D filaments is brimming with new possibilities and exciting innovations. From sustainable materials to specialty formulations that address specific industry needs, the evolution of 3D filaments is capturing the imagination of creators everywhere. As we continue to explore and experiment, who knows what advancements are yet to come? One thing is for sure: whatever happens, the journey will undoubtedly shape the future of how we create, design, and manufacture in ways we are only beginning to understand.

So, whether you’re a DIY enthusiast or an industry professional, keep your eyes peeled for the next wave of 3D filament innovations—adventure awaits!