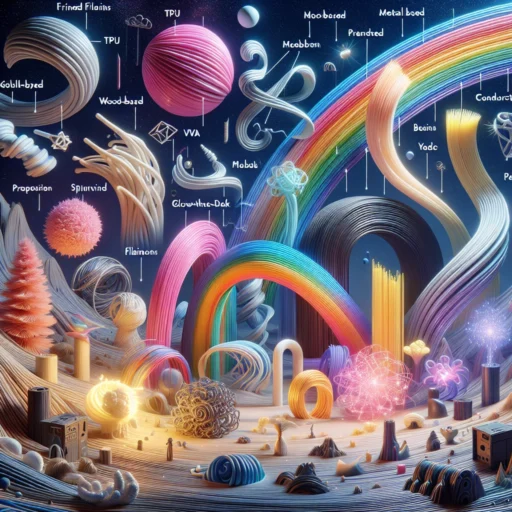

Exploring the World of Flexible and Specialty Filaments

In the ever-evolving landscape of 3D printing, filament selection is akin to choosing the right paintbrush for an art project—a decision that can make all the difference in the final masterpiece. While PLA and ABS remain the go-to basics for beginners, there’s a whole universe of flexible and specialty filaments just waiting to be explored. Whether you’re a DIY enthusiast, a professional designer, or a curious hobbyist, understanding the nuances of these materials can unlock new creative possibilities.

What Are Flexible Filaments?

Flexible filaments are a breath of fresh air in the 3D printing world. Unlike their rigid counterparts, these materials can bend, stretch, and flex without breaking. The most popular type of flexible filament is TPE (Thermoplastic Elastomer) and TPU (Thermoplastic Polyurethane). Both have gained a reputation for being user-friendly while offering a unique rubber-like quality that can be super handy in various applications.

Imagine printing custom phone cases, wearable tech, or even soft toys—all made possible with flexible filaments! They also allow for fantastic grip and shock absorption, making them perfect for items that need to endure stress or handle frequent use.

When printing with these filaments, it’s essential to keep a few things in mind. For instance, they tend to require slower print speeds and specific settings to achieve the best results. It can be a bit of trial and error at first, especially if you’ve been working with standard filaments. But once you get the hang of it, the results can be incredibly rewarding.

The Appeal of Specialty Filaments

While flexible filaments open doors to new forms and functionalities, specialty filaments can elevate your designs to the next level. These materials encompass a wide range of properties and finishes that can drastically alter the appearance and functionality of your printed creations.

Some noteworthy specialty filaments include:

-

Nylon: Known for its strength and flexibility, nylon is perfect for printing durable parts. It’s a fantastic choice if you need something that can withstand wear and tear, like gears or mechanical parts. However, it can be tricky to work with due to its tendency to absorb moisture.

-

Wood Fill: If you’re dreaming of that rustic, wooden finish without the hassle of actual lumber, wood fill filament might be your best friend. It mixes PLA with wood fibers to create prints that look and feel like wood. Think vases, tabletop games, or artistic sculptures—it’s like bringing the outdoors inside!

-

Metal Fill: Want to give your prints a metallic look? Metal fill filament, which contains tiny metal particles suspended in a plastic base, can give your 3D creations a stunning metallic finish. Keep in mind that these filaments can be abrasive, so they may require a hardened nozzle for printing.

-

Glow in the Dark: Perfect for fun or functional items, glow-in-the-dark filaments finish off prints with an otherworldly glow. They’re ideal for toys, night lights, or even safety features around the house.

-

Carbon Fiber: This is for those who want an extra kick in their project’s durability without adding excessive weight. Carbon fiber filaments are typically made with a base material (like nylon or PLA) reinforced with carbon fibers, leading to incredibly strong yet lightweight parts.

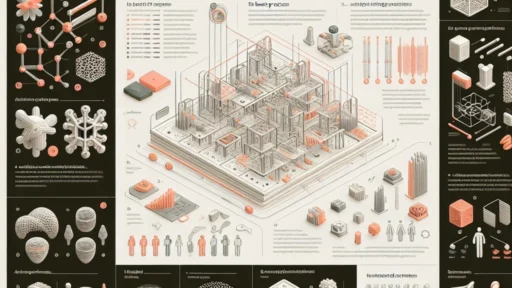

Tips for Working with Flexible and Specialty Filaments

Navigating the world of flexible and specialty filaments doesn’t have to be daunting. Here are a few tips to help you on your journey:

-

Adjust Your Print Settings: As mentioned, flexible filaments usually require slower print speeds. Experiment with different settings to find what works best for your printer and filament type.

-

Clean Your Nozzle: Especially with abrasive specialty filaments, regular maintenance of your nozzle is crucial. Keep it clean to ensure smooth and consistent flow.

-

Store Wisely: Many of these filaments, especially nylon and wood fill, can absorb moisture. Store your filaments in a dry, airtight container to preserve their properties.

-

Don’t Be Afraid to Experiment: One of the best aspects of working with 3D printing is the chance to innovate. Try mixing filaments or altering settings to discover new textures and finishes. You might stumble upon a unique combination that becomes your new favorite!

The world of flexible and specialty filaments is as diverse as it is exciting. The materials you choose not only define the functionality of your prints but also their aesthetic appeal. So whether you’re crafting a sturdy tool or a whimsical decoration, there’s a filament out there just waiting for your creative touch. Embrace the experimentation, learn from the process, and let your imagination run wild—it’s all part of the 3D printing adventure!