Navigating the Challenges of Large Format 3D Printing

In recent years, 3D printing has evolved from a niche technology used mostly by hobbyists and inventors to a game-changing tool in industries ranging from aerospace to healthcare. Among the exciting advancements in this field is large format 3D printing, which enables the creation of larger and often more complex structures than ever before. However, with great size comes great responsibility—along with a unique set of challenges that can make large format printing a little bumpy. If you’re considering diving into this expansive world, here’s what you need to know.

The Size Matters

First things first: when we talk about large format 3D printing, we’re not just referring to a printer that can spit out bigger objects. We’re talking about machines that can create parts several feet in length, width, and height. This capability opens up a universe of possibilities, allowing the production of anything from architectural prototypes to automotive parts.

However, larger items mean longer print times. While a small model might take a few hours, large prints can stretch into days or even weeks. Managing this time commitment requires not only patience but also meticulous planning. Print failures or errors during such lengthy processes can result in significant material waste and even project delays. Keeping an eye on the printer while it works its magic becomes a necessary part of the process, often transforming print runs into a labor of love.

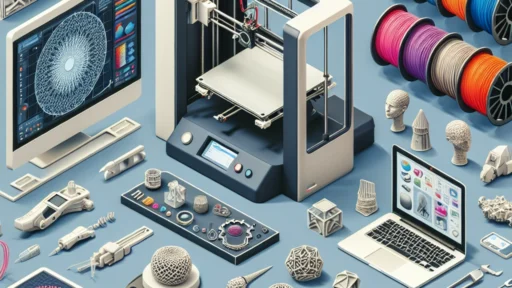

Material Matters

Another key challenge in large format 3D printing lies in the material used. While many desktop printers work with popular thermoplastics like PLA or ABS, large format 3D printers often utilize industrial-grade materials like Nylon, PETG, or even metals. These materials can have different properties, such as varying degrees of flexibility, strength, and temperature resistance.

Selecting the right material is essential not only for the structural integrity of the finished product but also for ensuring compatibility with the printer itself. Remember, larger prints generally require more robust materials to avoid issues like warping or cracking during the cooling process. The choice of material combines science and art—finding the right balance can feel a bit like a chemistry experiment.

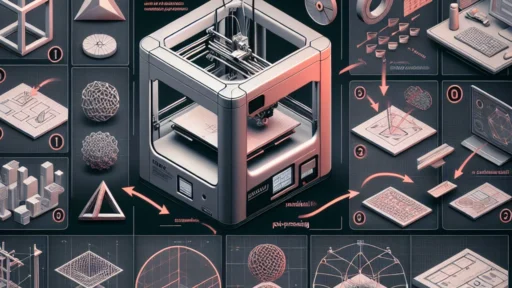

Calibration and Maintenance

The complexities of large format printers extend beyond just materials and time management. Calibration becomes exponentially important. During the printing process, slight misalignments can lead to disastrous results, resulting in wasted materials and time. Unlike their smaller counterparts, large format printers have multiple axes and components that need to be calibrated accurately to produce a seamless print.

Regular maintenance is also essential. Large printers are more complicated and, consequently, more susceptible to breakdowns. Keeping the print bed level, ensuring no dust or debris interrupts the printing process, and replacing worn-out parts can become a full-time job. Investing in a quality printer, as well as committing to a regular maintenance schedule, can save both time and resources in the long run.

Environmental Factors

Don’t forget about the environment where your large format printer resides. Humidity, temperature fluctuations, and even dust can significantly affect print quality. Large prints are particularly susceptible to warping, especially if they face sudden temperature changes. A stable, climate-controlled environment is ideal to minimize these risks, but that may require additional investment.

The Learning Curve

As with any new technology, there’s a learning curve to large format 3D printing. Whether you’re adapting existing designs to suit larger printing areas or learning how to troubleshoot failures, it’s essential to dedicate time and resources to familiarize yourself with the equipment. Online forums, tutorials, and communities can be invaluable resources in this regard, helping you speed up the learning process while connecting with others who share your passion.

A World of Possibilities

Despite the challenges, the rewards of large format 3D printing can be transformative. Imagine fabricating entire furniture pieces, automotive body parts, or sculptures in intricate detail. While the hurdles may be daunting, the opportunity to innovate and create is worth the journey.

As you navigate the highs and lows of large format 3D printing, remember that every challenge is a chance to learn and grow. With a little patience, the right materials, and a knack for problem-solving, the possibilities are indeed extensive. So take a breath, gear up, and dive into this remarkable frontier of design and manufacturing. Who knows what incredible creations await you?